What’s most astonishing is the speed at which it took place.

During the span of 40 days, InkSmith went from a small education technology company to one of the largest producers of personal protective equipment (PPE) in Canada.

“On the morning of March 20, a doctor from the Kitchener-Waterloo Academy of Medicine came by and told us how critical the shortage of PPE supply was,” says Laurier alumnus Jeremy Hedges (BA '15), founder and president of InkSmith.

“We said, ‘Okay, let’s jump in, let’s do this.'”

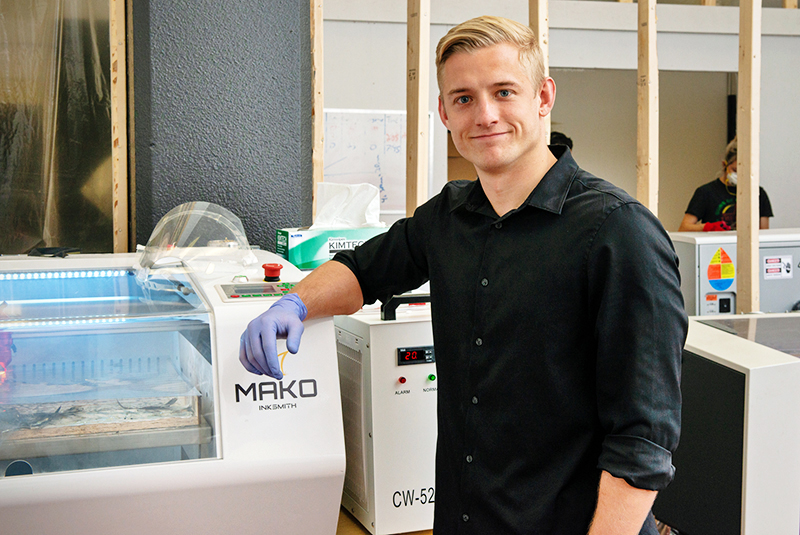

Laurier graduate Jeremy Hedges, the founder and president of InkSmith, a Kitchener-based company that has grown to become one of the largest producers of personal protective equipment in Canada.

Hedges soon transformed his Kitchener-based company to produce 3D-printed face shields needed to protect frontline healthcare workers fighting COVID-19. When the first shields were printed, there was great anticipation among InkSmith team members.

“We were all excited and even a bit surprised with how well the first ones turned out,” says Denisa Dica (BA '18), a Laurier alumna who works in customer and technical support at InkSmith. “But we were even more excited that we could do something to help people. That was huge for us.”

– Denisa Dica

Four days later, the new face shields received Health Canada approval and production was ramped up. Soon after, InkSmith developed a new laser-cut version of the shield that could be mass-produced – and received a little help from Laurier.

InkSmith was in urgent need of water chillers to cool its laser-cutting machine, so Hedges and Dica reached out to Ron Daniels, program coordinator at Laurier's Science Maker Lab. Daniels was able to quickly disinfect and deliver required parts, boosting the company’s capacity to manufacture the shields.

By May 1, InkSmith had produced over 1 million face shields and was increasing output to 250,000 per day to fill a federal government order of 10 million face shields, making the company Canada’s largest supplier. The InkSmith team named its new piece of personal protective equipment the “Canadian Shield.”

“It really felt like light speed for the first few weeks and the scale of things is much different,” says Hedges. “We’ve gone from six people to 150 people in a span of 40 days.”

Both Hedges and Dica said that InkSmith was not alone in its effort. As well as Laurier, other community partners contributed.

“The local school boards stepped up with their 3D printers and started printing different components for us,” says Hedges. “The community really rallied. It was a great example of everyone coming together.”

Hedges and Dica say their time at Laurier contributed to the development of the Canadian Shield, both practically and philosophically.

“I took psychology and biology at Laurier, but I was also the first student hired in the Science Maker Lab,” says Dica. “That’s where I learned CAD, 3D printing, laser cutting and all of the technology I use on a daily basis now. All of those skills helped me to have input into the design of the shield as it is today. My time at Laurier was instrumental in helping create this.”

Hedges says it is important to him that Canada never again finds itself facing a shortage of personal protective equipment, if or when another major health crisis strikes.

“By the time we're past the pandemic, InkSmith will be making surgical masks, N95 masks and a variety of other PPE," says Hedges. "So the next time we’re in a crisis we'll have Canadian manufacturing capacity.”